Ok, so we’ve decided to put the garden down to grass and decided if we are going to use seed or turf. Now it time to start. Get your weed killer out and CAREFULLY read the instructions. This will tell you if you need to dilute the chemical, by how much, what to use to spread it over the weeds, what safety precautions to take, how much to apply and when. Wait for a dry still day, you do not want the chemical washing off before its has had time to act or it blowing onto anywhere it causes unwanted damage, and get on wit it.

Now wait. Glyphosate weed killers take time to work; 10 to 14 days is perfectly normal. The first thing you may notice is the grasses start to turn faintly yellowy, but you have to look carefully. Shortly afterwards the weeds will all turn yellow and die; except for the green streaks where you missed. Now some of you will now be saying if you’ve carefully applied the weed killer you should have missed none of it. You’ve never done it. Trying to apply a more or less clear liquid over a garden without missing any patches is very difficult as you cannot clearly see where you’ve been and it is always best to err on the side of caution. Killing off bits of your neighbour’s lawn is likely to cause a degree of friction! Don’t worry, simply go out and treat any bits you’ve missed. You are probably asking why no bright spark has thought of a solution to this; well I’ve been down that road and every turning seems to lead to a dead end.

Once the weeds are well and truly dead, its time to prepare the ground. Start by clearing anything you can see on the surface such bits of rubble, scaffolding poles or anything else the builders saw fit to file away in the garden. You should now have a clear patch of soil with just the remains of some dead weeds. The next step is to cultivate the ground. Much is said in gardening books about digging, single digging, double digging, etc. Little of it covers the problem that is it is very hard work and very slow. I did once double dig a small area, as much as an experiment as any thing else and I don’t recommend it one bit. To be realistic you are going to have to use a machine. At this point you have to consider how big a machine can you get in the garden, its no good hiring a 600mm wide machine if it has to be taken through a 450 mm wide gate way, and how big a machine is it going to be practical to use in the space you’ve got.

You now have three options:

- Buy a machine

- Hire a machine

- Get someone to do it for you

The problem with buying a machine is what you are going to do with it afterwards and a machine good enough for the job is going to be very expensive. Hiring a machine means you have to operate it yourself and you have to consider getting to and from the hire shop. Any good hire shop will provide you with good instructions on how to use the machine and for a charge will deliver and collect it but using one is still hard work and you have to consider is it for you. Finally you could pay someone to do it for you and I’m sure you will be able to find a selection of people in the local free papers able to provide the service but you have to accept the cost.

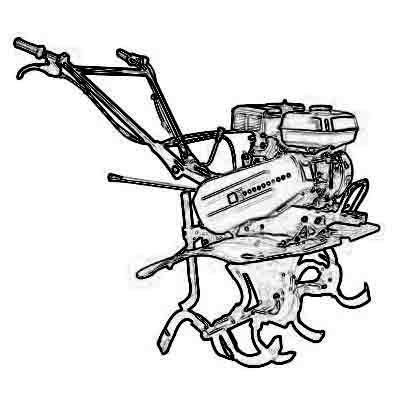

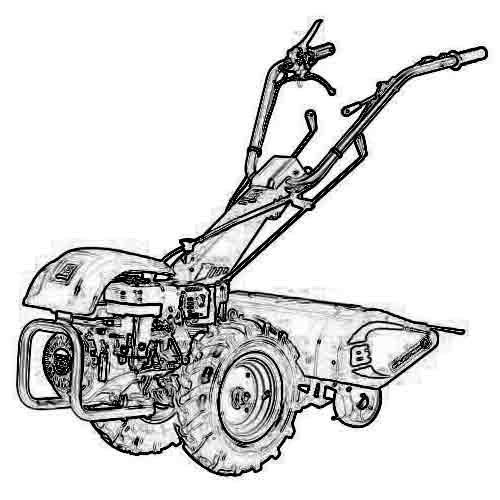

You may have noticed I haven’t mentioned what machine to use. In reality this is going to be a rotator cultivator, generally know as a Rotavator. Rotavator is in fact a trade name of the Howard Rotavator Company but has undergone the same transition as Hoover; where a trade name becomes so synonymous with a product it becomes a generic term for it. Rotory cultivates come in two basic flavours: tine driven and rear tined.

The tine driven ones have a set of rotating tines set under a motor and controlled by a pair of handles. The main problems with these are they tend to be rather light weight and are more prone to running away. This is where the tines rather than dig in run along the ground dragging the operator behind them. The rear tined machines have a pair of wheels under the motor and a set of rotating tines behind them; with the operator standing behind the tines holding the handles. These are heavier duty machines and less prone, though not immune, to running away. Being bigger and more complex machines they are both more expensive and heavier to move from site to site.