-

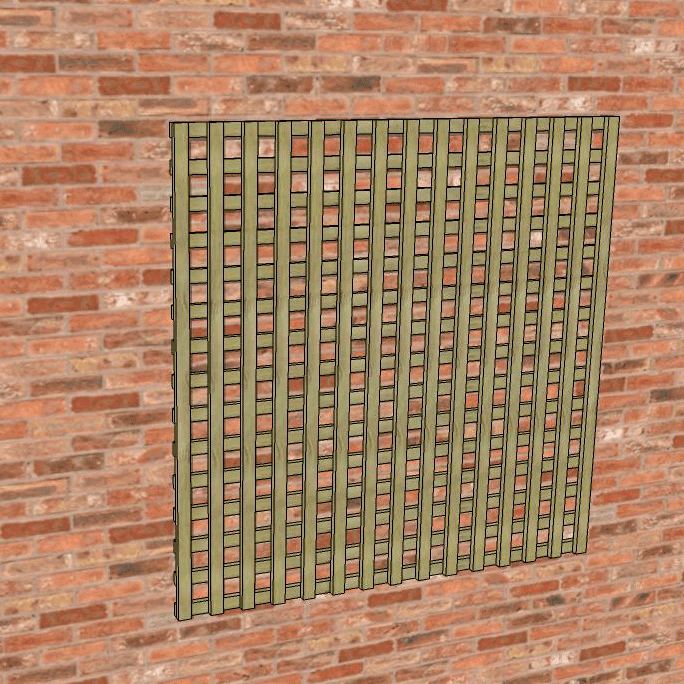

Fixing trellis to a wall

Trellis is a very effective way of training climbers against a wall and can either be bought or made from scratch. Fixing it to the wall though can present problems but with a little care result can be both durable and effective. Equipment: Method:

-

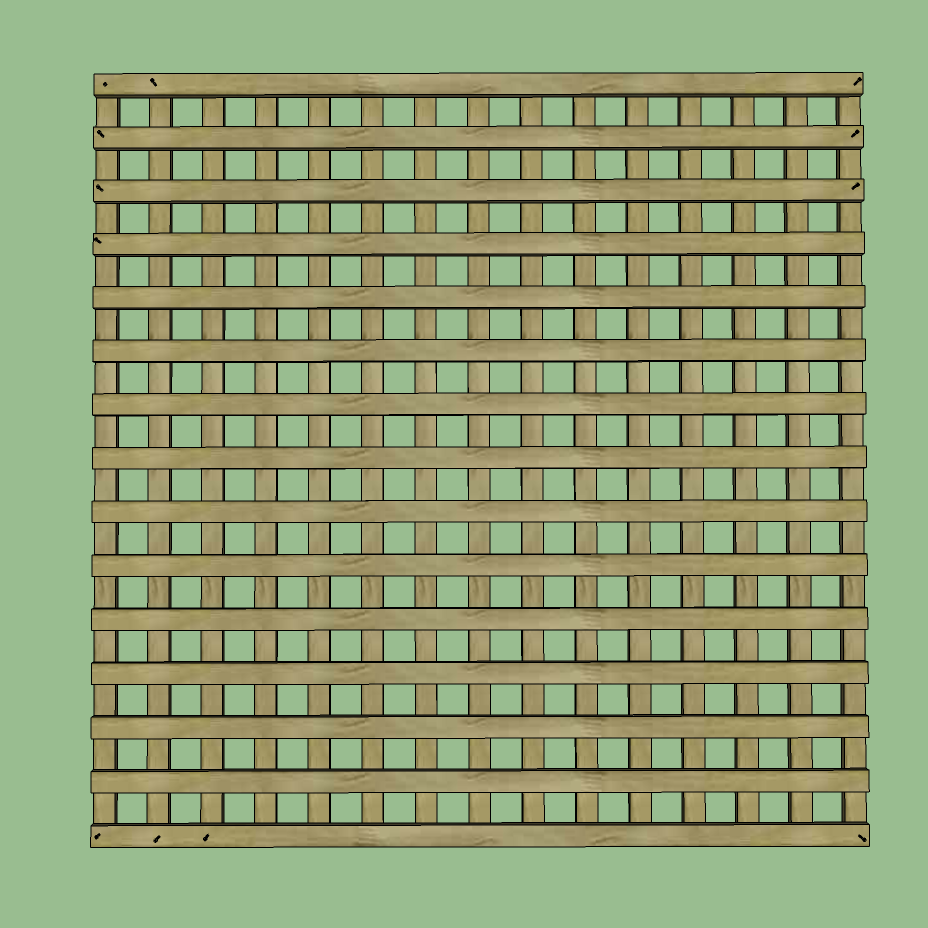

How to make trellis

Trellis can be purchased ready made from garden centres and DIY stores but it is in a limited range of sizes, you only have one spacing for the lathes and it is often quite light weight. A far better way is to make it yourself from pressure treated timber and you can chose any sizes…

-

How to build a sleeper retaining wall

Retaining walls are never cheap or easy but building one from timber railway sleepers is probably as cheap and easy as you are likely to find. As the sleepers are simply screwed together their construction is well within the abilities of most people without any specialist building experience. Equipment: Spade Sledge hammer Tape measure Pick…

-

Bond, English

This is one of the commonest method of constructing a brick wall which is more than ½ a brick thick and consists of alternating courses of heads and stretchers.

-

The minor wall building materials

Metal Though important in building is garden use is rather limited but can if used carefully can be very effective. The term metal encompasses a vast range of material, many used since ancient times, and the suitability of a particular one will depend on the individual use planned. Reinforced concrete This material combines concrete and…

-

The main wall building materials

Brick One of the oldest and most durable building materials; its variability, flexibility, durability and strength has made a ubiquitous walling material. Traditionally made from dried earth the centuries of use and development has lead to a very sophisticated produce now mass produced in millions each year in the UK alone. The earliest bricks were…

-

Parts of a Wall

Garden walls are constructed from 5 distinct elements: Subgrade The first, the subgrade, is the ground the entire structure stands upon and so its stability and load bearing ability determines on whether the wall is going to remain standing. For these reasons the wall foundation should be onto undisturbed ground that has not been built…

-

Types of garden walls

Free standing The simplest walls are free standing and these are normally used when boundaries are walled. In the UK garden walls above 2 metres high, unless they face the public highway when its 1 metre, require planning permission. That said this is only a basic guideline and local rules or covenants can often apply…

-

Garden walls

The wall is one of the oldest manmade structures, and its use in gardens is as old as gardens themselves. The word comes from the West Saxon weall which in itself comes from the Latin vallum meaning a rampart and in the garden walls are used as a natural development of earth ramparts. Initially walls…